Pick and Place Robots

Central Conveyors offers cutting-edge pick and place robotic solutions designed to transform your manufacturing and logistics operations.

Our robotic systems excel at repetitive tasks requiring precision, consistency, and reliability—enabling your business to increase productivity whilst reducing operational costs.

What Are Pick and Place Robots?

Pick-and-place robots are automated systems specifically designed to retrieve objects from one location and precisely position them in another. These versatile robots form the backbone of many modern manufacturing and logistics processes, ranging from simple component transfers to complex assembly operations.

Our pick and place robotic solutions can be configured with various end-of-arm tooling options to suit different applications, including:

-

Multiple tool changes

-

Assembly

-

Packaging

-

Bin picking

-

Precision placement

-

Quality inspection

Types of Pick and Place Robots

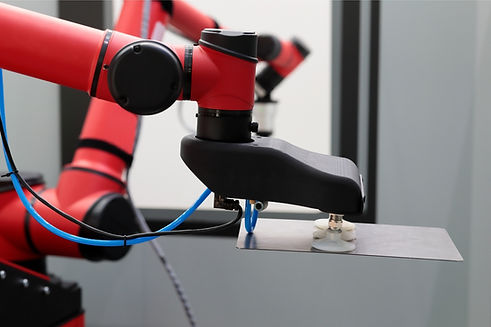

Articulated Robots (5 and 6-Axis)

Offering exceptional flexibility, our 5- and 6-axis robotic arms provide the most versatile pick-and-place solutions. The 5-axis configuration excels at simplistic single-plane transfers, whilst our advanced 6-axis robots can handle complex movements across multiple planes and orientations. These can be further enhanced with gantry or linear tracks for larger applications typically used in automotive and manufacturing sectors.

SCARA Robots

Specialised for fast, precise horizontal movements, SCARA (Selective Compliance Assembly Robot Arm) robots are ideal for high-speed assembly lines and rapid pick-and-place operations where cycle time is critical.

Delta Robots

Our high-speed delta robots excel at rapid, repetitive movements. Their parallel link structure allows for exceptional speed and precision, making them perfect for packaging applications where multiple robots can work in synchronisation to achieve demanding throughput targets.

Collaborative Robots

The expanding world of collaborative robots offers safe, transportable automated picking that can work alongside human operators without the need for safety barriers. These robots combine flexibility with ease of deployment, making automation accessible even for smaller operations.

Advanced Technologies

Vision Systems

Integration of 2D and 3D vision technology enhances our robotic systems by identifying the orientation and position of parts along conveyor sections, allowing the robot to make intelligent decisions for accurate picking and placing.

End-of-Arm Tooling

We offer bespoke gripper solutions designed for specific applications:

-

Electric Grippers: Precise control for handling diverse objects

-

Vacuum Grippers: Ideal for smooth, flat surfaces and delicate items

-

Magnetic Grippers: Perfect for ferrous materials

-

Specialised Tooling: Custom-designed for unique product requirements

Control Systems

Our robotic systems feature intuitive programming interfaces that make them suitable for even small-volume productions. The systems can be seamlessly integrated with your existing equipment and production management software.

Benefits of Pick and Place Automation

-

Increased Productivity: Robots work consistently with minimal downtime, significantly boosting throughput

-

Enhanced Precision: Achieve repeatable accuracy to microscopically tight tolerances

-

Labour Cost Reduction: Reallocate staff to more value-added tasks

-

Improved Quality: Eliminate human error from repetitive processes

-

Greater Flexibility: Quick changeovers between different products and configurations

-

Compact Design: Maximise operational space with optimised footprint

-

Reduced Waste: Precise handling minimises product damage

-

24/7 Operation: Continuous production capabilities

-

Data Integration: Real-time performance monitoring and analysis

Why Choose Central Conveyors

Central Conveyors delivers unparalleled expertise to provide solutions precisely matched to your material handling requirements.

Unlike many competitors who operate as intermediaries with limited product offerings, Central Conveyors maintains an in-house team of dedicated project managers, design specialists, and mechanical engineers. This approach enables us to engineer bespoke systems that align exactly with your specifications whilst maintaining cost-effectiveness.

Beyond our core design, manufacturing, and installation services, Central Conveyors ensures exceptional post-purchase support. Each system is accompanied by comprehensive documentation, including operational manuals and detailed spare parts catalogues.

Our central East Midlands location provides optimal accessibility to service clients across the UK and European markets.

For detailed information about our product range, contact our team on 01509 816064.

The Complete Conveyor System Solution

Whether you need a simple belt replacement or a comprehensive automation solution, our team is here to support you. Contact us today.

Find Us:

Central Conveyors Ltd,

Unit 13 & 14, Kernan Drive,

Swingbridge Trading Estate, Loughborough,

LE11 5JF